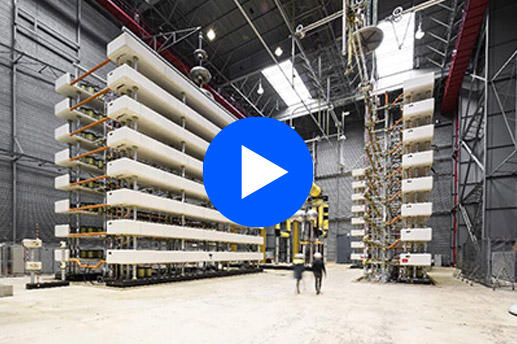

High power testing station dedicated to high current & high voltage electrical equipment

3300 MVA power testing station connected to the 420 kV 50 Hz network with several indoor cells and outdoor areas:

- short-circuit tests up to 130 kA – 3 s;

- Making and breaking tests for circuit breakers up to 100 kV – 25 kA using direct method and up to 420 kV – 63 kA using synthetic method;

- synthetic facilities 800 kV / 2x3,6 MJ ;

- internal fault tests and power arc tests.

Three-phase heat run tests up to 50 kA that may be coupled to a 230 m experimental overhead line.

Additional facilities: mechanical tensile tests, 100 m overhead lines for short-circuit tests, power arcs test facility for insulator strings.

Download documents

-

Uninterrupted current tests PDF - 3.46 MB

-

Short-circuit tests PDF - 3.1 MB

Technical capabilities

High voltage breaking tests

Demonstrate the capacity of a circuit-breaker to interrupt all types of current (fault, inductive loads, capacitive loads).

All the fundamental sequences: terminal fault, short line fault, phase opposition, capacitive and inductives breaking, busbar transfer,

| Main hall | Synthetic Testing Hall | |

| Sizes (L x W x H) |

Indoor Hall 32 m x 21 m x 31 m |

Synthetic facilities 100 m x 30 m x 30 m |

| Testing capacity | 3300 MVA 4 test transformers connected to the 400 kV 50 Hz power grid Testing voltage from 11,6 to 246 kV |

2 capacity banks of 3,6 MJ Charge voltage +/- 800 kV Current injection Weil-Dobke type 2 and 4 parameters TRV Power frequency recovery frequency |

| Circuit-breaker up to 100 kV - 25 kA in direct method Circuit-breaker up to 420 kV - 63 kA complete pole in synthetic method |

||

| Performed tests | All the fundamental sequences: terminal fault, short line fault, phase opposition, capacitive and inductives breaking, busbar transfer, DC current breaking test (ask the lab) |

|

Short-circuit tests

Demonstrates the ability of a switchgear to support a short-circuit current.

| Indoor Hall | Outdoor areas | |

| Sizes (L x W x H) |

32 m x 21 m x 31 m Internal hall | External dall16 m x 100 m Scope of the overhead line of 100 m with intermediate gantry Area of power transformer testing |

| Testing capacity | 3300 MVA 4 test transformers connected to the 400 kV 50 Hz grid Voltage vacuum tests from 11,6 to 246 kV |

|

| Up to 130 kA – 3 s | Up to 80 kA – 3 s | |

| Performed tests | Short time withstand current on switchgears Short circuit tests on power transformers up to 240 MVA 400 kV or 360 MVA 235 kV Short circuit on cables, conductors and accessories, security equipment (earthing devices), surge arresters Direct accuracy tests on measurement transformers |

|

Internal fault Power arc

Creation of high-current electric arcs.

| Internal default area | Insulator string area | |

| Sizes (L x W x H) |

Secured area for internal default tests Burial area of insulated cable |

|

| Testing capacity | 3300 MVA 4 test transformers connected to the 400 kV 50 Hz power grid Testing voltage from 11,6 to 45 kV |

|

| Up to 80 kA – 3 s | Up to 80 kA – 3 s | |

| Performed tests | Internal fault on cable terminations or measurement transformers Fault on insulated cable, buried or not |

Internal fault on cable terminations or measurement transformers Fault area on isolated cable, buried or not |

Additional facilities

Temperature rise: permanent current tests to demonstrate non-thermal run-off of equipment.

Mechanics: resistance tests to mechanical stress or mechanical endurance of materials

| Heating | Mechanical | |

| Sizes (L x W x H) |

15 m x 11 m x 12 m hall | 16 m x 9 m x 12 m hall |

| Testing capacity | 13,8 MVA 50 kA in three phase low voltage (single phase or two phase tests possible as well) 5 kA under 2,7 kV max |

2 tripods of 8 m 1000 daN force 2 tripods of 4 m 500 daN force |

| Performed tests | Heating on circuit breaker, switchgears, measurement transformers, GIS, busbars… Scope of 230 m experimental overhead line that can be coupled with temperature measurement, sag, mechanical tensile, etc ... |

Static force or alternating traction on measurement transformers, switchgears, circuit breakers, cable terminations, bushings, |

Power testing station dedicated to medium voltage electrical equipment

500 MVA power testing station connected to the 225 kV 50 Hz network with several indoor stands and outdoor areas:

- three-phased short-circuit tests up to 40 kA;

- making and breaking tests for circuit breakers up to 24 kV – 12.5 kA using direct method;

protection tests for power transformers; - overload and overcurrent tests;

- internal fault tests on MV cells and power arc.

Three-phase heat run tests up to 4 kA.

Additional facilities: mechanical endurance on MV equipment, sound-proof room for noise measurements, 1000 m experimental MV overhead line.

Technical capabilities

Medium voltage breaking tests

Demonstrate the capacity of a circuit-breaker to interrupt a medium voltage current (fault, inductive loads, capacitive loads).

| SEMT A | TRV Bench | |

| Sizes (L x W x H) |

4 indoor testing cells 5,5 m x 9,2 m x 5 m |

|

| Testing capacity | 2 x 250 MVA 2 test transformers connected to the 225 kV 50 Hz grid Testing voltage from 3 to 24 kV |

2 capacitiy banks 2 parameters TRV 24 kV RMS / 60 kV peak 50 Hz recovery frequence |

| Circuit-breaker up to 24 kV – 12,5 kA in three-phase direct method | ||

| Performed test | All the fundamental sequences: terminal fault, phases opposition, capacitive and inductives breaking. Break fuse |

|

Short-circuit / Internal fault

Demonstrates the ability of a switchgear to support a short-circuit current.

| SEMT A | External area | Short range of overhead line | |

| Sizes (L x W x H) |

4 internal cells 5,5 m x 9,2 m x 5 m |

3 m x 5 m | MV overhead line of 1000 m |

| Testing capacity | 2 test transformers of 250 MVA connected to the 225 kV 50 Hz power grid Test voltage from 3 to 24 kV Test current up to 40 kA |

1 test transformer of 250 MVA connected to the 225 kV 50 Hz power grid Test voltage from 3 to 24 kV Test current up to 10 kA |

Testing voltage from 3 to 24 kV |

| Performed test | Short circuit on transformer and other MV equipment Internal fault on MV equipment | Protection against transformers cut Internal fault and short circuit Surge arrester |

Fault detector testing, … |

Additional facilities

Temperature rise: permanent current tests to demonstrate non-thermal run-off of equipment.

Mechanics: resistance tests to mechanical stress or mechanical endurance of materials.

| Heating | Mechanical | Soundproof room | |

| Sizes (L x W x H) |

5,2 m x 4,6 m x 5,9 m hall | 5,2 m x 4,6 m x 5,9 m hall | 5,2 m x 4,6 m x 5,9 m hall |

| Testing capacity | 4 kA three-phase or single phase Room temperature up to 50°C |

1400 operations/day (C-O) | Background noise of 18 dB(A) |

| Performed test | Heating on all type of LV/MV equipment |

Mechanical life on HTA cells, powertrain, IP / IK degree | MV transformer noise measurement |