As the world's leading nuclear operator, the EDF Group is the leader of a strategic industrial sector of excellence and has unique expertise in this field. One of the priority roles of R&D is to support and perpetuate this major asset for the Group.

R&D is working to protect EDF's assets by making its actions part of the process of improving the safety of installations, seeking to improve performance and extend the operating life of reactors.

To do this, R&D researchers rely on unique testing resources and laboratories. Discover some of these emblematic laboratories!

We offer you here a first overview of our laboratories and testing facilities, not exhaustive. Please visit our page regularly, as more content will be added in the coming weeks and months.

Your browser does not support javascript.

To enable you to access the information, we suggest you view the video in a new tab.

Ignis: Full-scale fire and safety installation for nuclear power plants

IGNIS is a test facility that is unique in the world for its modularity, designed to meet the challenges of fire safety in nuclear power plants.

Discover a short video, in immersion mode.

PERICLES

PERICLES Platform… At 360°

Located at EDF Lab Chatou, PERICLES is a testing platform that reproduces the conditions in which a nuclear power plant’s cooling circuit operates. Discover it in this virtual tour!

Your browser does not support javascript.

To enable you to access the information, we suggest you view the video in a new tab.

WAAM: a way forward for the manufacture of large parts

Wire Arc Additive Manufacturing (WAAM) is one of the additive manufacturing processes being closely studied by EDF R&D.

Find out more about this technique, derived from welding, which can be used to manufacture metre-sized parts.

Your browser does not support javascript.

To enable you to access the information, we suggest you view the video in a new tab.

Discover also our R&D gem on additive manufacturing: a complete file to know everything about this revolutionary process.

Cold Spray, a promising process for repairing large components

Installed on the EDF Lab Les Renardières site, Cold Spray is an innovative manufacturing process based on the use of additive manufacturing or 3D printing. The aim is to give us greater control over our component manufacturing and repair processes!

The Chemistry, Microbiology and Ecotoxicology laboratories

Visit the Chemistry, Microbiology and Ecotoxicology laboratories... At 360°

These three laboratories can be used to study biological and chemical phenomena that affect the availability, safety and and performance of production facilities. Discover them in this virtual tour!

Your browser does not support javascript.

To enable you to access the information, we suggest you view the video in a new tab.

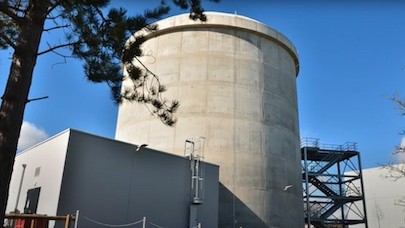

VERCORS

EDF R&D studies the resistance of reactor enclosures

R&D has built a 1/3 scale model of a nuclear reactor vessel, which allows accelerated aging studies of concrete vessels.