In 2022, the teams of the High-Power Test Station (Station d’Essais de Grande Puissance, SEGP) carried out a test campaign at the request of SERGI TP, manufacturer of Transformer Fast Depressurization Systems (TP).

The TP is defined in the 2020 edition of the NFPA (National Fire Protection Association) Code 850 for Transformer Fast Depressurization Systems:

“A passive mechanical system designed to depressurize oil-filled equipment such as transformers, current-limiting reactors, bushing cable boxes, or load tap changers a few milliseconds after the occurrence of an electrical arc”.

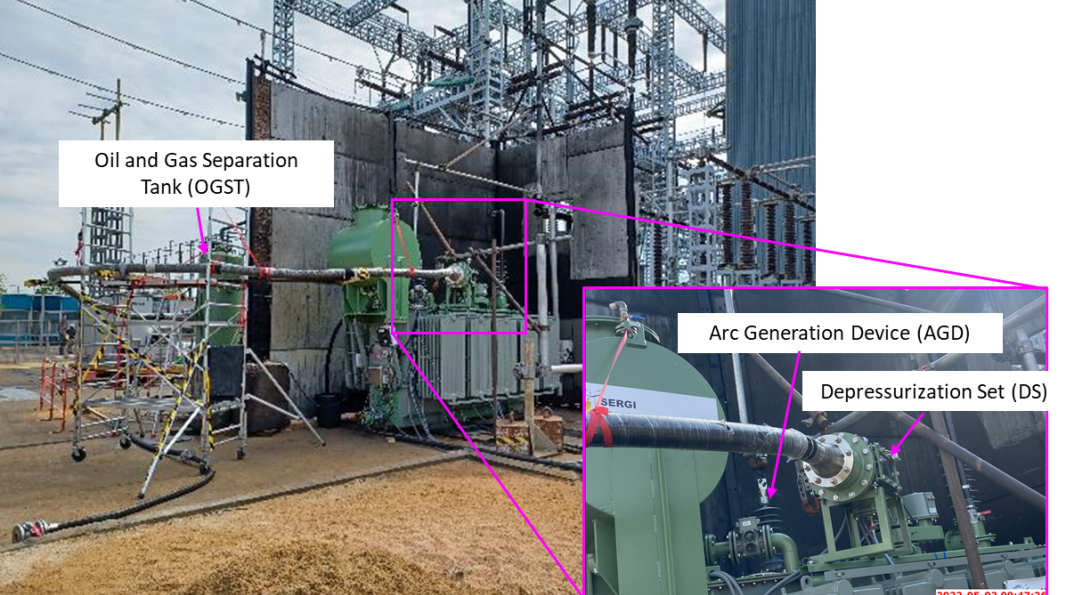

The test campaign consisted of generating arcs inside a sealed oil-filled transformer tank. At the time of an arc ignition, the variation of dynamic pressure generated by gas production reaches the TP Depressurization Set (DS), expelling an oil/gas mixture from the tank, ensuring its depressurization.

A 7.5 MVA transformer had been modified for the tests purpose, it was equipped with dynamic pressure sensors (8) and static (2), temperature sensors, as well as 2 Arc Generation Devices (AGD): one located at the bottom of the transformer tank, and the other at the top. They were connected to the station busbars for producing arcs from the Arc Generation Device fuse wires. The arc voltage could be modified by adjusting the distance between the electrodes. An unprecedented assembly was carried out during 2 weeks, with pipes, an Oil and Gas Storage Tank (OGST) for gas identification and the volume measurement, control cabinets and an oil treatment plant shown in the attached pictures.

Arc currents between 10kA and 20kA with arc energies between 680kJ and 4,040kJ have been achieved.

Thanks to the know-how of EDF Lab's technical teams, our customer has collected a large amount of data related to the TP operation. We are delighted to have accompanied SERGI TP in this test campaign.